Gas exploration is often conducted in remote and harsh environments, such as deserts, plateaus, and seas, with harsh working conditions. This places high demands on the performance of exploration equipment.

Among these, power supply is particularly crucial, as it serves as the core foundation for ensuring drilling, data collection, communication, and safety systems.

Since these operations are far from the power grid, you need high-performance alternators to ensure a continuous electricity supply, avoiding impacts on efficiency and reducing the downtime risk. What is the best high-performance alternator for gas applications? Read on to learn more!

Not all power generation systems for oil and gas can meet the stringent demands of gas projects. They should be designed to address:

The primary challenge in gas exploration is the extremely harsh working environment. On land, working areas are often located in remote regions far from the power grid, with poor transportation access. These areas may also face extreme cold or hot weather, strong sandstorms, high humidity, or other factors that can affect devices' performance, such as sand and dust clogging cooling and filtration systems of generators.

On offshore platforms, high salt spray corrosion, wave impacts, and typhoons further increase the difficulty of equipment maintenance and may even lead to risks such as short circuits or fires.

Gas rigs depend on a wide range of electrically powered systems such as drills, mud pumps, top drives, lighting, communication tools, and safety monitoring systems. All these require a continuous and stable power supply to function without interruptions.

Even a short-term power loss can halt operations and affect the work process. Therefore, the alternator must be capable of operating under high load conditions for extended periods and possess rapid response capabilities (such as automatic voltage regulation) to handle sudden increases in power demand.

To operate efficiently and safely in gas exploration projects, alternators must be specifically engineered to meet the demands of this unique application. So, what makes a high-performance alternator ideal for gas-based use? They should feature:

Gas operations may face extreme cold, such as -20°C in Siberia, or scorching heat, with temperatures exceeding 50°C in some Middle Eastern regions. Therefore, the optimal alternators should possess:

· Cold-start capability: Equipped with a preheating system to ensure reliable startup in extremely cold conditions.

· Heat dissipation optimization: Features an efficient cooling system (e.g., high-flow fans) to prevent overheating shutdowns.

· Low-temperature-rise design: Excessive temperature rise can damage insulation layers, shorten bearing lifespan, and reduce operational efficiency. Generators with lower temperature rise can maintain higher performance over long-term operation.

Plus, materials, insulation, and structural integrity must all support temperature resilience.

Energy waste is not an option in remote gas locations. Fuel logistics are a hassle, and efficiency is crucial. A high-performance alternator should provide:

· Fuel-efficient design: Optimized fuel injection system to improve fuel utilization.

· Power factor optimization: Reduces reactive power loss and increases effective power output.

This translates to reduced operational costs and optimized energy usage, making it ideal for natural gas power solutions where efficient power matters most.

Dust, sand, and rain spray are constant threats. Given the exposure to wind-driven storms, monsoons, and sea waves, it is crucial for natural gas power solutions to have a high IP (Ingress Protection) rating.

A high-performance alternator with an IP23 rating or above can common resist water and dust intrusion, reducing the risk of internal short circuits or coil corrosion. This is critical for both land-based and offshore gas rig operations.

Corrosive elements like salt, oil, and some chemicals are often present in gas fields. High-performance alternators are built with materials and coatings that resist corrosion to ensure longevity. Plus, they will also be enclosed in a way that prevents rust, erosion, or damage caused by these chemical agents. This will protect your investment over the years of operation.

In natural gas exploration operations, high-performance alternators must possess excellent impact and vibration resistance to withstand dynamic load environments such as land drilling rig movement, wave impacts on offshore platforms, and transportation jolts. The ideal generator should incorporate:

· Heavy-duty steel frames and high-elasticity vibration dampers to absorb high-frequency vibrations and prevent structural fatigue.

· All fasteners should be secured with self-locking nuts to prevent loosening caused by prolonged vibration.

· For marine applications, generators should maintain a continuous power supply capability even under ship tilting conditions.

These design features collectively ensure the generator's reliability and long alternator lifespan under physical stress, meeting the safety requirements for electrical equipment in natural gas projects.

Choosing high-performance alternators is not simply a technical choice; it is a financial and operational decision that affects the overall success of a gas exploration or processing project. Unlike in regular applications, performance in gas environments can cause chain reaction failures, environmental risks, and worker safety issues.

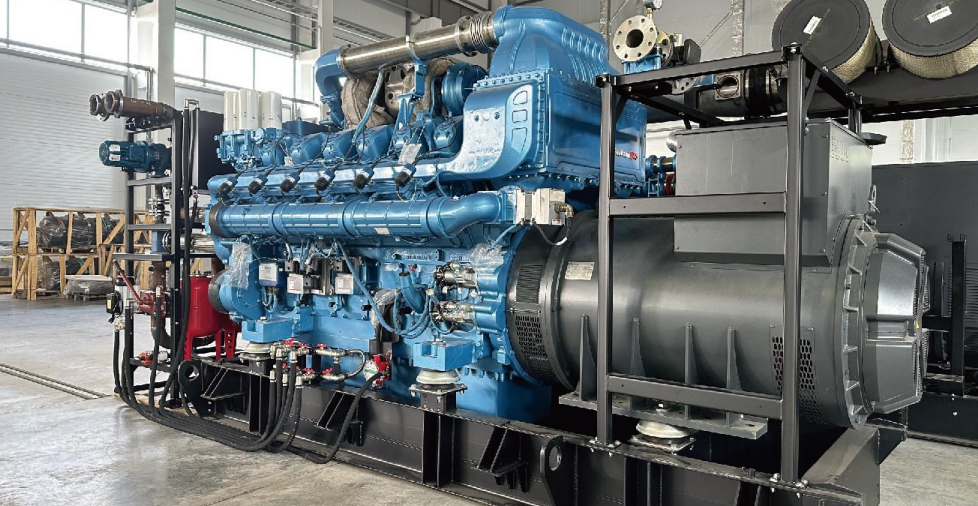

If you are looking for high-performance alternators that check every box, EvoTec alternators are superior choices for your gas power projects. At EvoTec, we understand the unique demands of gas exploration and our alternators are engineered specifically for the most challenging environments. From desert rigs to offshore platforms, EvoTec alternators deliver power that you can count on.

Our high-performance alternator series features models with wide temperature adaptability, high energy efficiency, and enhanced waterproof and dustproof designs (IP23 or above). All of our alternators go through rigorous testing to meet corrosion resistance standards, so they thrive in salt-heavy coastal to offshore conditions. Moreover, we also pay special attention to impact resistance.

EvoTec alternators have been used in various power generation systems for oil and gas, helping businesses minimize downtime, reduce operational cost, and increase overall productivity.

Power reliability is the foundation of any successful gas operation. Selecting the right high-performance alternators ensures stability, safety, and cost efficiency for your project.

EvoTec alternators are purpose-built to meet these demands with superior design, exceptional performance, and reliable service. Contact EvoTec now for efficient and long-lasting power generation in gas applications!